Our Projects

Proper Material Processing

Dry Kiln

19th Century artillery system equipment builds require hardwood materials to meet specific processing requirements as defined in the United States Ordnance Department’s Land Service Of The United States 1849-1865 drawings and specifications. Timbers for use must clear special selection processes from standing live trees to finished material for use in manufacturing. Once complete, our dry kiln will enable Columbia Mountain Artillery to meet these requirements applying proper material processing in preparation for upcoming projects!

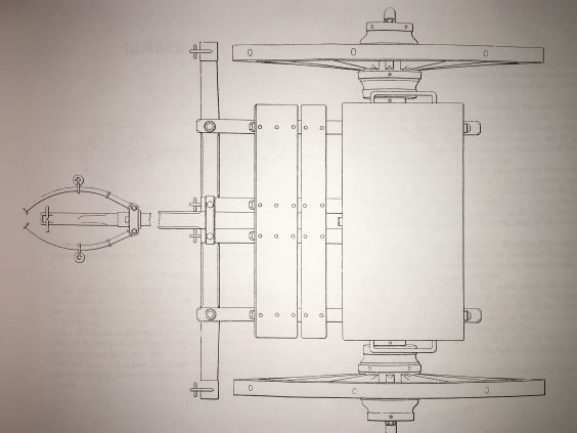

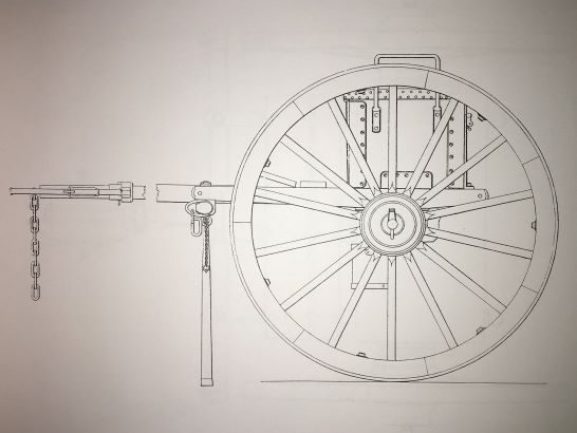

Limber Project

The limber

We are well on our way adding a very important and functional element to our collection. We are building a full-scale Field Artillery Limber. The limber is a two-wheeled cart designed for coupling to a variety of field carriages essentially forming a 4-wheeled unit for the purpose of increasing maneuverability over rough terrain. The limber allowed for 1 ammunition chest which also offered a seat for up to three soldiers when fast movement was ordered or required. A limber is arguably the most universal and necessary part of an artillery battery system. One Limber provided coupling to multiple carriages enabling mobility at any given time. Interchangeability of wheels across battery equipment carriages included but were not limited to the caisson, battery wagon, and the traveling forge! Most important was the ability to use a wheel if necessary to replace a wheel on gun carriages if strategic movement or unfortunate retreat during battle was required and a damaged wheel would otherwise result in potential loss of a key asset.

The collection is growing! Check back from time to time and follow us as the project evolves!

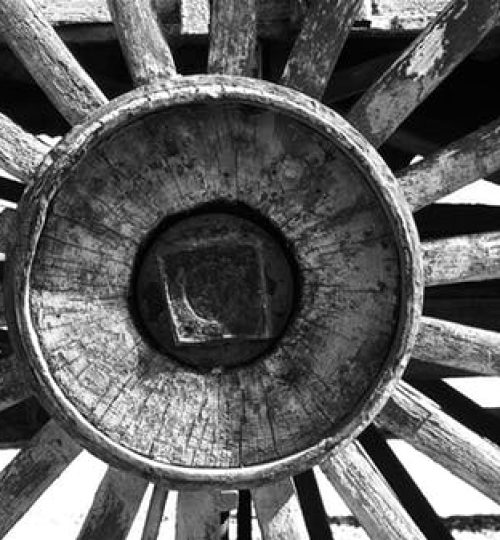

Wheels Project

wheels

We are exceptional at what we do! Part of being exceptional is recognizing that being exceptional doesn’t mean we are exceptional at everything! Wheels require special manufacturing processes, techniques, wheel manufacturing equipment, and above all… an artist as much as a skilled tradesman! To fill this need Anvil Wagon Works in Livingston, Montana has been chosen as our shop of choice, they are exceptional at what they do and we are pleased to work with them on a wheel build project. We are excited looking forward to the new limber wheels! Here are some examples and samples of whats to come and what’s been done. Also a few pictures of some old wheels from days gone by. If only they could tell their story!